Simulation of substructures

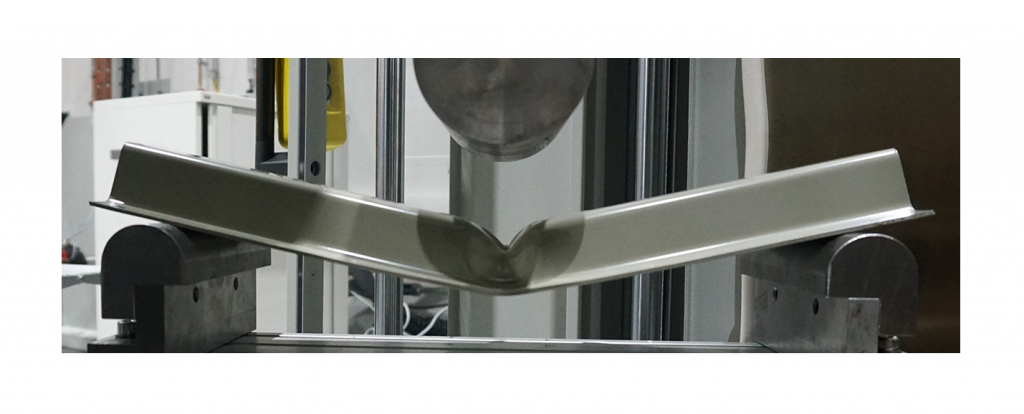

Experimental testing of components or assemblies is necessary for the validation of material models, as well as for quality control during series production or the analysis of special stress conditions. The challenge in this context is to build test rigs in which the components are loaded in the same way as in the real environment. The GNS Research and Methods Group , which consists of simulation engineers with an additional experimental background, offers the entire range of activities in this field, from the identification of suitable components, through preliminary test design, to experimental validation.

Component Behaviour

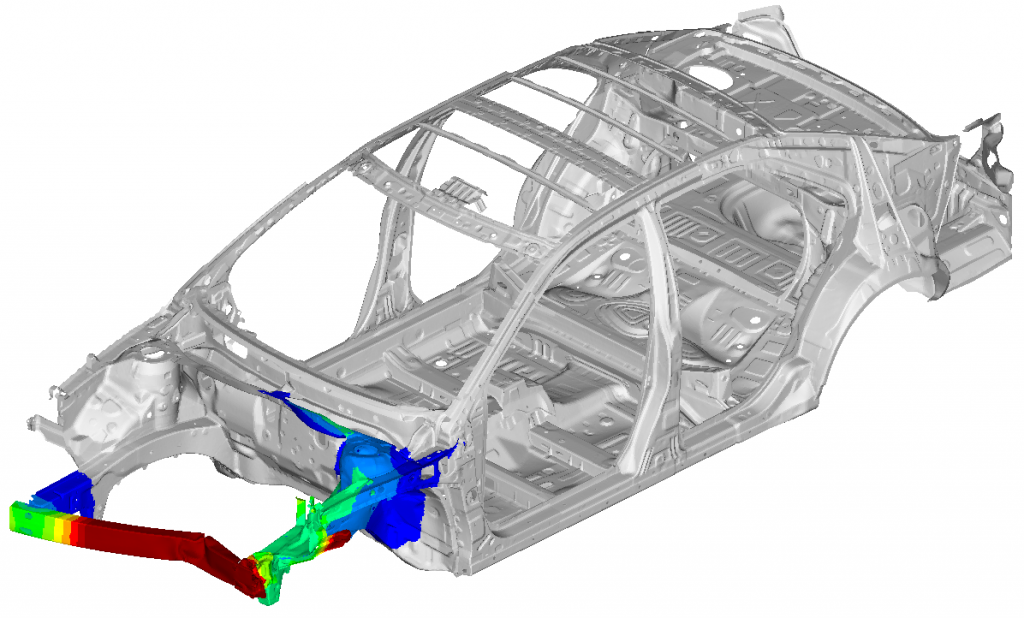

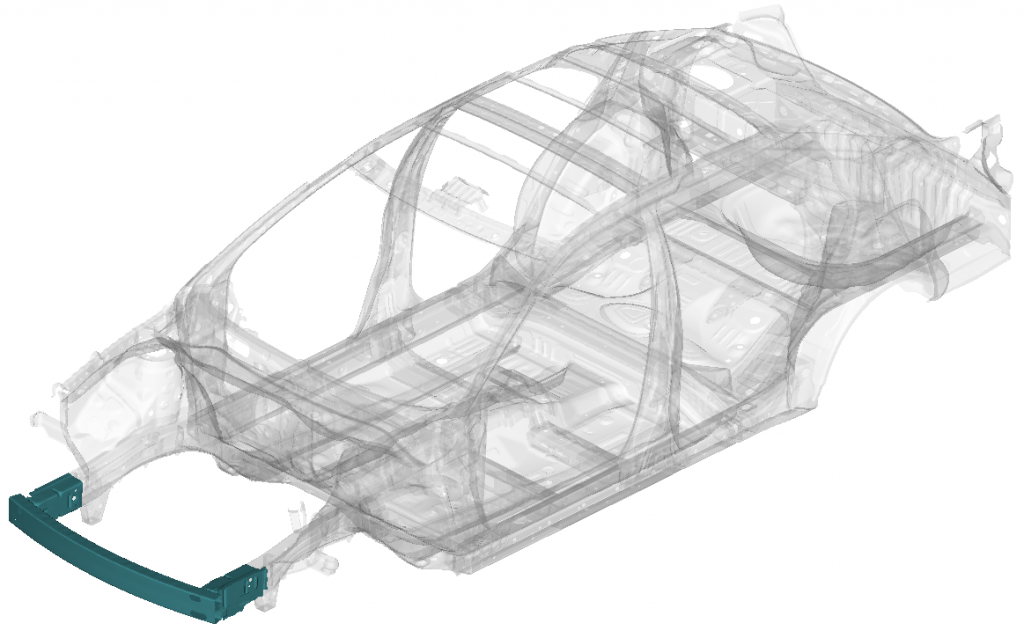

In order to analyze the required components, a stress analysis is carried out considering the situation in the base model. In addition, the Connecting-Island-Algorithm from the EEGO project can be used for a further analysis. As a result of these analyses, detailed knowledge of the respective stress state is obtained. This information allows a precise statement about the components required for the test and the boundary conditions that are decisive for a successful test setup.

Preliminary design

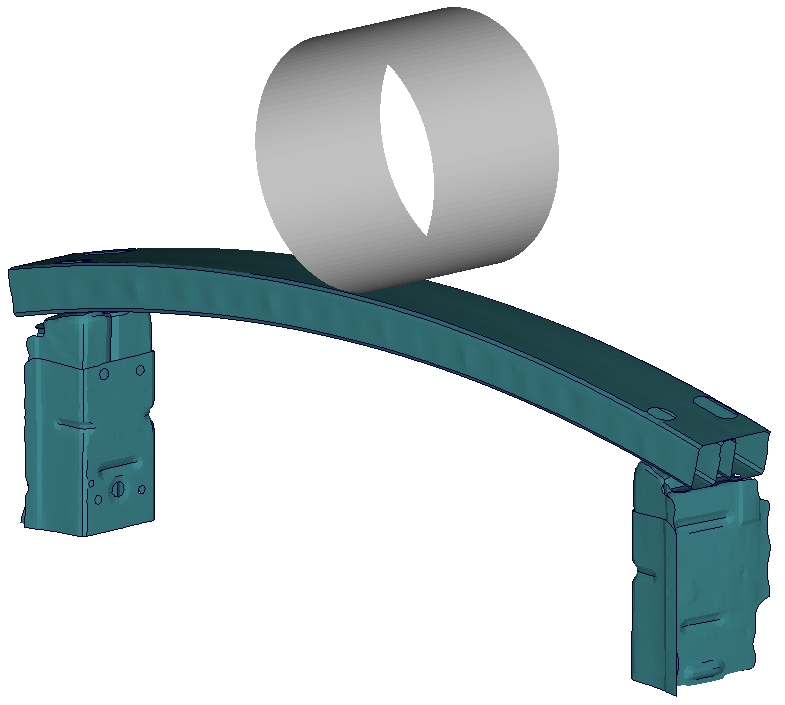

Based on existing structures or, if applicable, previously conducted stress analyses, the simulative preliminary design of the test setup is carried out in close coordination with our customers and in dependence on the possible conditions on site. The focus hereby lies on a robust, cost-efficient and repeatable experimental setup as well as on an easily implementable validatable measurement chain. In parallel, the transferability of the results from the component test to the installed condition is continuously checked. Adjustments to material models, geometry and connections are among the frequently performed tasks here.

Validation

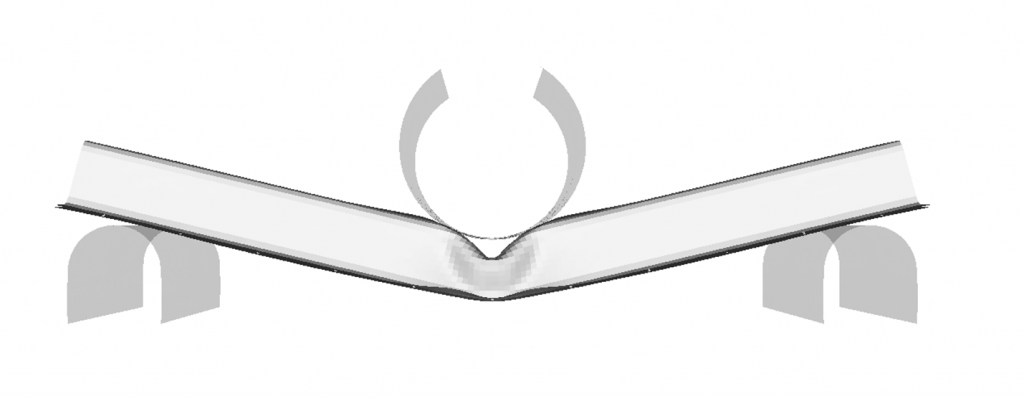

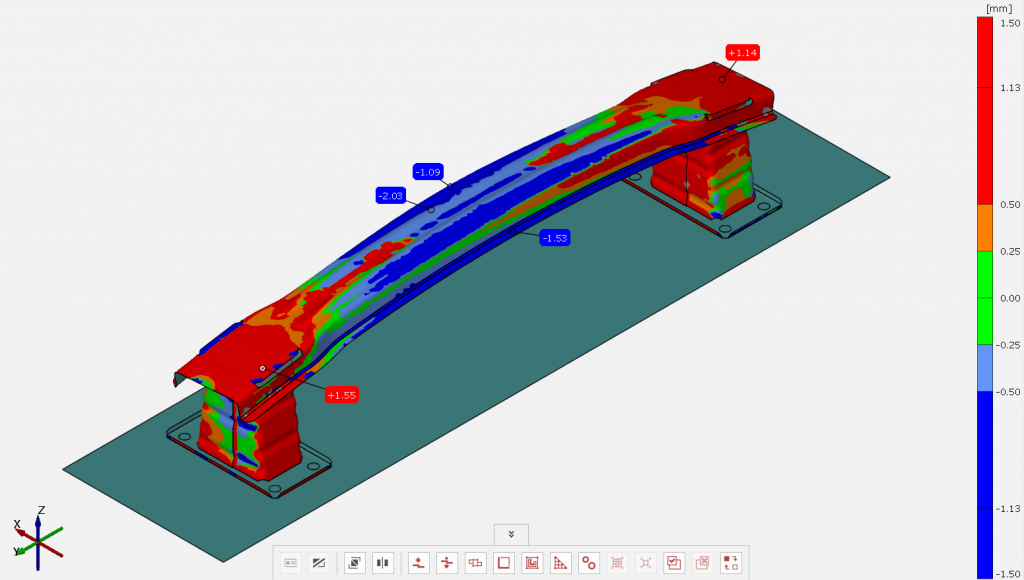

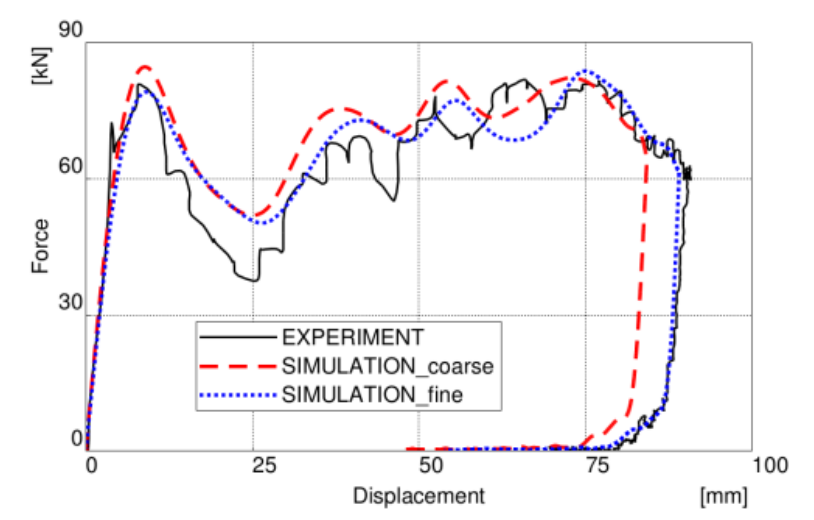

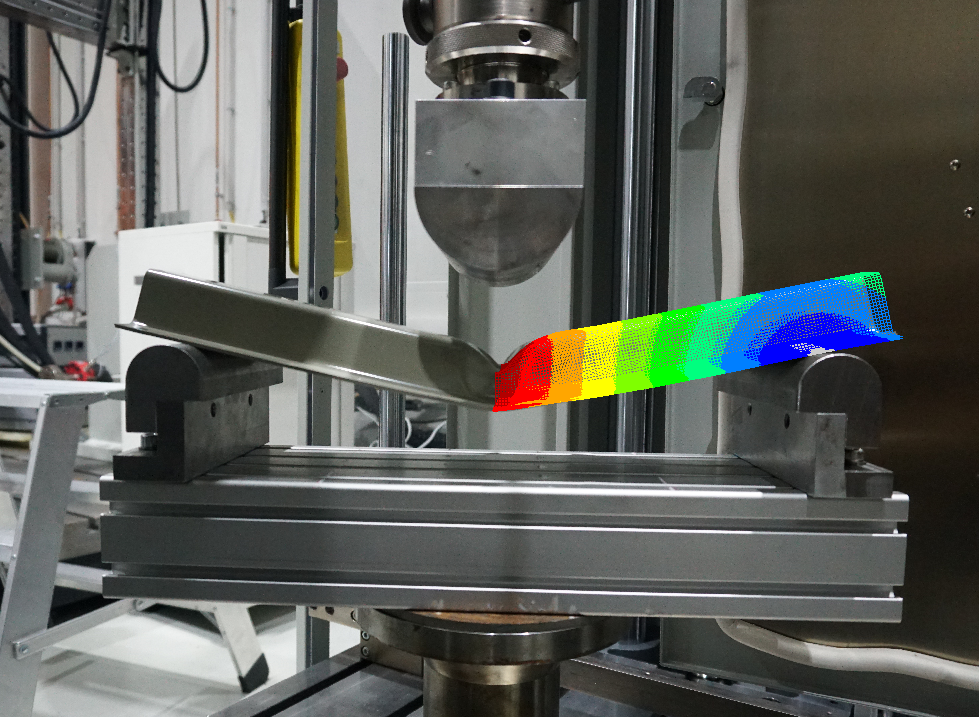

The comparison of a simulation model with experimental data can usually provide valuable information about the used material models, the modeling techniques or geometry deviations of the model. The range of work carried out by GNS in this area extends from simple comparisons of force-displacement or stress-strain curves, through to geometry comparisons based on DIC measurements. Also, detailed error analyses can be performed, and proposals developed in order to minimize the deviations between simulation and experiment. All this can help to sustainably improve the prediction accuracy in the CAE development process and thus save costs and time.

Publications

- 2017/06 - D. Feuer, A. Hatscher, P. Marcks, M. Löcker, R. Schwarzer, E. Ince: Adaptive virtual and physical benchmarking method for new steel grades in car structures; Conference Paper, Steels in Cars and Trucks 2017, Nordwijk, Netherlands